Integrated platform for in-depth design exploration

Discovery AIM

Integrated platform for in-depth design exploration.

ANSYS Discovery AIM seamlessly integrates design and simulation for all engineers, helping them to explore ideas and concepts in greater depth.

Discovery AIM provides a single platform for simulation-driven product development. With guided workflows to promote best practices, you can take advantage of best-in-class ANSYS solver technology to the fullest. Easy to learn and use, it offers unmatched versatility, speed and precision to optimise designs and take them to the next level.

Whether performing thermal, electromagnetic, structural, fluid or various multiphysics combinations, Discovery AIM eliminates the need for any other simulation software for designers.

Upfront simulation

Up to 80 percent of the cost of a product’s development is determined by the decisions you make early in the design process. Upfront simulation is digitally exploring design concepts and testing critical design choices early in the product lifecycle using simulation. Upfront simulation gives you the information to make informed decisions, reduce costly physical prototypes, and avoid unworkable designs down the road. Upfront simulation helps you bring innovation to market faster and less expensively.

Design engineering

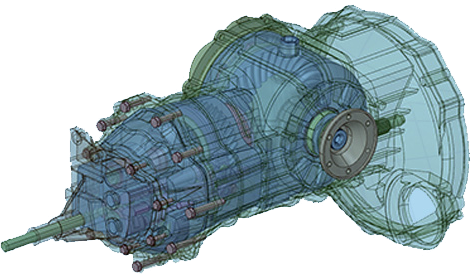

ANSYS Discovery AIM makes upfront simulation easy by combining intuitive, guided workflows, accurate simulation results and optimisation in a complete simulation tool. Integrated geometry modelling based on ANSYS Discovery SpaceClaim technology helps you create new 3D concept models, or edit/repair existing geometry. Whether a simulation includes electromagnetics, thermal, structures, or fluids or combinations thereof, all aspects of simulation workflow are included in the single-window design, which enables you to predict complete product performance with results you can trust. Discovery AIM’s powerful parametric and optimisation capabilities can automatically explore the design space thoroughly and find the best design faster.

Customised solutions

ANSYS Discovery AIM makes it easy to deploy simulation throughout an engineering organisation. You can customise Discovery AIM’s user interfaces to comply with your company’s standards for simulation, and create simulation templates for your unique industry applications. Because Discovery AIM includes fluids, structures, thermal and electromagnetics simulation capabilities, engineers only need to learn one tool, reducing training time and costs.

Take designs to a new level.

With the freedom to design and innovate without the complexities of traditional CAD, speed up your design and engineering processes and get your products to market faster.

To discuss your specific requirements and arrange a free trial demonstration, call us on +44 (0) 20 7436 9004 or email us.